Welcome To Trinity Graphic

A True Visionary in Prepress Supplies & Services

A True Visionary in Prepress Supplies & Services

Bring Your Vision to Life

Since inception, Trinity Graphic has been a family business focused on quality, creativity, and collaboration. Our mission is to serve flexographic printers with quality prepress supplies and service to help you achieve your goals.

Concentrating on the web-fed markets of flexo and rotogravure, Trinity Graphic offers flexo platemaking and photopolymer embossing die-making services, along with shrink sleeve distortion and consulting/training support.

With continued investments in cutting-edge technologies, Trinity Graphics has the capabilities to work with an array of materials and softwares to ensure the highest level of success for your final products.

Operating globally for over 40 years, the Trinity team has a thorough understanding of the equipment and methodologies required for printing in this demanding market. Our expert people and processes ensure you have a knowledgeable prepress partner on your side.

With a mission to continually invest in new technology, to enhance the quality of our products, and to constantly challenge and re-define industry standards and practices, your success is our #1 priority.

TRINITY GRAPHIC SOLUTIONS

PREPRESS SUPPLIES & SERVICES

Trinity Graphic knows flexo plates! With extensive experience in the science of platemaking, Trinity Graphic can work with a wide range of materials and packaging applications.

We work closely with photopolymer experts to improve our product quality continuously and tailor our plates for your unique packaging needs. As experts in prepress supplies and service, we are well versed in a wide variety of flexo plate materials and their unique advantages, suitability, and compatibility. Therefore, we stock a wide variety of materials to ensure quick availability of compatible and high-quality plates to get your production up and running.

Trinity has several plate washout systems, enabling us to produce large format plates. Our plates range in thickness from .045” to .25”, including the solvent-free thermal-processed fast plates. Trinity Graphic plates are engineered to suit a variety of OEM specifications and tailored to suit your packaging needs.

With Trinity, you get expert solutions with expert support to keep your package printing profitable. Contact us today to get started.

Our in-house solvent reclamation enables us to thoroughly wash plates faster, due to less solvent absorption into the photopolymer material.

Trinity utilizes ESKO’s HD Flexo which is a high resolution plate that consistently delivers smooth vignettes, sharp details, intense colors, and high contrast, resulting in increased print quality.

We also offer ESKO’s SambaFlex, a transitional/hybrid screening, which improves the smoothness of your flexo highlights, while maintaining mid-tones and shadows.

PREPRESS SUPPLIES & SERVICES

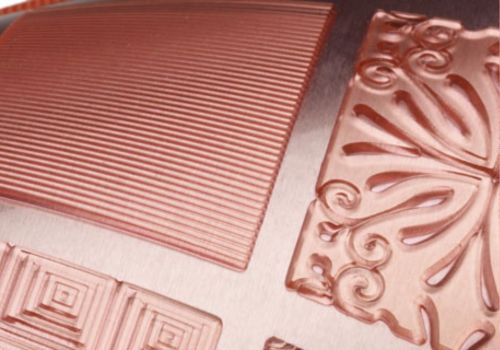

As the industry leaders of the photopolymer embossing process, Trinity Graphic is renowned for its ability to produce the highest quality embossing dies for even the most difficult projects.

Photopolymer embossing is a cost-effective alternative to steel embossing dies. Male and female photopolymer plates, with a high durometer, are applied to two die blanks, positioned into a rotary die station on a web fed press. These plates utilize specially formulated photopolymer, in conjunction with proprietary techniques, to produce plates with the appropriate durometer to withstand the extreme pressure of embossing.

This process is often used to replicate paper patterns, though with our wide range of capabilities, Trinity can create almost any pattern, custom or replica, to fit your prepress supplies and service needs.

To discuss your next embossing project, contact our team to discover the efficiency and effectiveness of our photopolymer embossing solutions.

Photopolymer embossing is a cost-effective, fast-turnaround alternative to engraved steel embossing cylinders. With their lightweight build and durability, your shipping costs will be drastically reduced!

Ideally suited for the cosmetic, food/beverage, and wine label markets, this process allows most substrates to have an embossed and/or debossed effect enhancing product appeal and creating a more high-end look to your finished product.

Trinity Graphic offers many unique and custom embossing patterns in our catalogue. Need a custom pattern? Our team can design or replicate almost any pattern you may need for your next print project.

The photopolymer embossing process works on a multitude of non-synthetic substrates. An evaluation can be made once we have received a sample of the stock. Trinity can provide embossed proofs prior to expensive press runs!

PREPRESS SUPPLIES & SERVICES

Shrink sleeves are an exciting trend in the world of packaging and represents the highest growth in flexographic printing. However, this opportunity brings with it a serious prepress challenge. As a shrink-sleeve label shrinks around a bottle or packaging, all of the graphics and embellishments on the label become distorted in proportion to the bottle or packaging dimensions. To compensate, all the graphics must be pre-distorted during prepress to ensure the final label appears as the designer intended.

At Trinity Graphic, we have the latest distortion measurement and design technologies to overcome any artwork challenges. Our artists have been designing for shrink since inception, with years of experience under their belt. Trinity Graphic can help you with all of your shrink sleeve artwork needs, whether you print via flexo, gravure, or digital. With a wide range of prepress supplies and services, choose Trinity Graphic as your print partner for all things flexo.

At Trinity Graphic, we have the latest software, scanners, and distortion measurement techniques to overcome your shrink sleeve artwork challenges.

Our pre-press artists have over 15 years of training and experience, many working in shrink sleeve design since the inception of this packaging type in the print industry.

With years of experience in shrink sleeve design under our belts, we know the best ways to hide seams, optimize space and highlight top content. Our team will work alongside you to not only distort, but collaborate on, your artwork for the best final print.

TRAINING SERVICES

In addition to our prepress supplies and services, Trinity Graphic provides specialized global consulting and training services to the flexographic, rotary letterpress, prepress, and general printing markets.

These services can be retained independently or in tandem with your print projects. A Trinity consultant will work with your team to develop custom education tracks and identify facility pain points.

Should you wish to establish an in-house prepress or platemaking facility, look to Trinity’s consulting team for direction. We have years of experience with equipment testing and will assist you in identifying the best platemaking equipment to fit your needs and budget. We do not sell equipment, therefore you know our recommendations are based on the best fit for your needs, and not for commission.

Contact the Trinity Graphic team today to discuss your training and consulting needs and we’ll get your team up to speed in no time!

In-house training programs are also available. We will train your personnel from the early stages of digital set-up and output through platemaking. Custom education tracks can be created to suite your unique training needs and goals.

We have years of experience with equipment testing and can help you identify the best equipment to fit your needs and budget. Please note, we do not sell equipment and our recommendations are made based on the best fit for your needs, not commission.

These services can be retained independently or in tandem with your print projects. A Trinity consultant will work with your team members to develop value-driven solutions and identify technical issues specific to your facility and processes.

TRINITY NEWS & INSIGHT

Shrink sleeve distortion is a crucial step in shrink sleeve printing applications. Shrink sleeves are labels that conform…

Printing plates are a crucial component in the flexographic printing process. As a maker and innovator of flexo plates…

As quality demands continue to grow, flexographic printing plates can make the difference between happy customers and rejected…

The Flexo industry has changed drastically over the past decade. Technology and processes that were once profitable, are…

HERE TO SERVE YOU

Thank you for your interest in Trinity Graphic! Please submit the form to send a message to the Trinity Graphic team or contact us directly using the information below.

1225 Tallevast Road

Sarasota, FL 34243, US

941-355-2636

800-451-1729

Trinity Graphic USA, Inc.

1225 Tallevast Road

Sarasota, FL 34243, US

941-355-2636