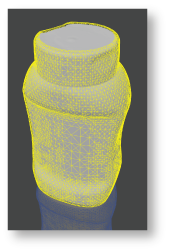

Shrink sleeve distortion is a crucial step in shrink sleeve printing applications. Shrink sleeves are labels that conform to the shape of a container when heat is applied, creating a 360-degree coverage of the surface. Distortion designing takes into account the unique properties of shrink sleeves and addresses the distortions associated with the shrinking process.

Trinity Graphic has been assisting flexo printers with various pre-press services for decades. We know a thing or two about the shrink sleeve manufacturing process and have collaborated with printers to achieve perfect shrink sleeve designs. Here are several reasons why shrink sleeve distortion pre-press design is important.

Container Shape Conformity

Shrink sleeves are designed to shrink and conform to the shape of the container when exposed to heat. Distortion designing ensures that the graphics, text, and images on the sleeve are proportionately distorted to appear correctly when the sleeve shrinks. This is critical for maintaining the integrity of the brand and the visual appeal of the packaging.

Shrink sleeves are designed to shrink and conform to the shape of the container when exposed to heat. Distortion designing ensures that the graphics, text, and images on the sleeve are proportionately distorted to appear correctly when the sleeve shrinks. This is critical for maintaining the integrity of the brand and the visual appeal of the packaging.

Containers come in various shapes and curvatures. Shrink sleeves need to be designed to accommodate these variations, ensuring that the label adheres properly and shrinks uniformly across the container’s surface. Shrink sleeve pre-press distortion accounts for the curvature of the container to prevent uneven or awkward shrinkage.

Maintain Brand Consistency

For products with distinct branding, consistency is key. Shrink sleeve distortion helps maintain brand consistency by ensuring that logos, colors, and other brand elements retain their intended appearance on the final packaged product. This consistency is crucial for brand recognition and consumer trust.

Without proper distortion incorporated, images and text on the shrink sleeve can become skewed and illegible during the shrinking process. Prepress distortion services from Trinity Graphic ensure that key design elements remain legible, recognizable, and aesthetically pleasing after the shrinkage.

Informed Designing

Distortion designing allows for the strategic placement of key design elements on the shrink sleeve. Designers can anticipate how the distortion will affect different parts of the label and position important information accordingly.

Distortion designing allows for the strategic placement of key design elements on the shrink sleeve. Designers can anticipate how the distortion will affect different parts of the label and position important information accordingly.

By accounting for the distortion in the design phase, designers can optimize the resolution, clarity, and color accuracy of the graphics. This ensures that the printed images on the final product meet the desired quality standards.

Minimize Production Challenges

Proper distortion designing can help minimize challenges during the production process. Designing with shrinkage in mind allows for more accurate and predictable results, reducing the likelihood of production errors and waste.

In summary, distortion prepress services are vital for achieving visually appealing shrink sleeve packaging. By accounting for the shrink percentage during the design process, printers can ensure their final design meets both aesthetic and functional requirements. Need assistance with your artwork? Trinity Graphic offers prepress shrink sleeve distortion services to give you peace of mind. Contact our team to request a quote today!

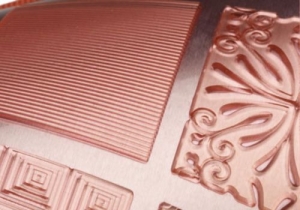

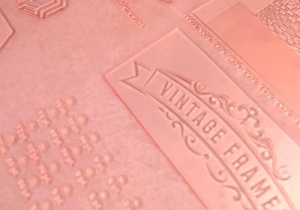

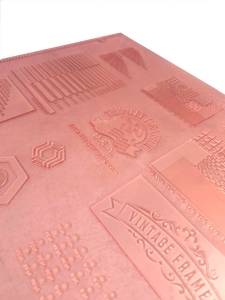

A top consideration when selecting plates is substrate compatibility. Different substrates, such as paper, plastic, or corrugated materials, require specific plate materials, durometers, and other characteristics to achieve the best print quality. Understanding the nature of your printing substrate is essential to choosing the right plates that achieve vibrant and durable prints.

A top consideration when selecting plates is substrate compatibility. Different substrates, such as paper, plastic, or corrugated materials, require specific plate materials, durometers, and other characteristics to achieve the best print quality. Understanding the nature of your printing substrate is essential to choosing the right plates that achieve vibrant and durable prints. Your plate handling and mounting processes can easily contribute to the efficiency, or inefficiency, of your print operations. Consider plates that are easy to handle during setup and mounting, as this can save valuable production time. Additionally, plates with visual registration features can help your team mount with precise and consistent results.

Your plate handling and mounting processes can easily contribute to the efficiency, or inefficiency, of your print operations. Consider plates that are easy to handle during setup and mounting, as this can save valuable production time. Additionally, plates with visual registration features can help your team mount with precise and consistent results.

At Trinity, we have a full team of on staff plate designers with years of experience in the flexo industry. Our team is trained in both the art of design and the science of print to ensure plate quality and performance is always at a maximum. When you partner with Trinity, you gain access to a full team of skilled designers eager to bring your print to plate.

At Trinity, we have a full team of on staff plate designers with years of experience in the flexo industry. Our team is trained in both the art of design and the science of print to ensure plate quality and performance is always at a maximum. When you partner with Trinity, you gain access to a full team of skilled designers eager to bring your print to plate.