Is it Time to Outsource Your Flexo Plate Making?

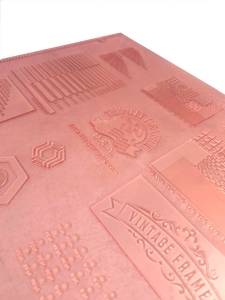

The Flexo industry has changed drastically over the past decade. Technology and processes that were once profitable, are now holding printers back from fully optimizing their shop floor. Printing plates and the flexo plate making process are becoming one of these notably cumbersome processes. With the insurgence of digital technology, along with staff and machine limitations, platemaking in-house may no longer be as profitable as it used to be.

At Trinity Graphic, we’ve specialized in the science and design of photopolymer printing plates for over 50 years. In our experience, there is a clear turning point for when a printer should begin outsourcing their printing plates. In this blog, we discuss the three main factors to examine when considering outsourcing your platemaking.

Is it time for a software upgrade?

A prepress department relies on various pieces of equipment and software working seamlessly together to produce high-quality plates efficiently. However, if any of this software becomes outdated or equipment requires upgrades, it can disrupt the delicate balance of your prepress operations. This often creates a domino effect—updating one piece of the puzzle may necessitate a complete overhaul of computers, operating systems, and software. These updates can cost up to $100,000.

Beyond the infrastructure investment required for these upgrades, printers also need to account for the time, effort, and troubleshooting involved with implementing a new system. After new systems are installed, additional resources are needed to train employees, onboard teams, and set up and distribute software licenses.

Faced with these challenges, many printers ask themselves: Should we continue managing this in-house, or is it time to outsource our prepress to an external partner? At Trinity Graphics, we leverage cutting-edge technology designed to work seamlessly with a variety of materials and equipment, ensuring premium-quality flexo plates for your success. Don’t let outdated machines and technology slow you down—take advantage of our state-of-the-art plate-making technology for fast turnarounds and reliable results when you outsource to Trinity Graphics.

Do you have skilled designers in-house?

The infamous staffing shortage in flexo. It’s not only happening with machine operators, assemblers, and production staff; flexo plate designers are in short supply, as well. Excellent plate design combines the creativity of design with the science and knowledge of the printing process. However, many graphic designers are trained in digital media design and lack the skillset for creating custom printing plates. It is imperative to work with a designer that has experience in photopolymer plate design. Once found, the questions then become: do you have enough work to maintain a full-time in-house plate designer? And do you have a manager skilled in design to step in for oversight and revisions?

At Trinity, we have a full team of on staff plate designers with years of experience in the flexo industry. Our team is trained in both the art of design and the science of print to ensure plate quality and performance is always at a maximum. When you partner with Trinity, you gain access to a full team of skilled designers eager to bring your print to plate.

At Trinity, we have a full team of on staff plate designers with years of experience in the flexo industry. Our team is trained in both the art of design and the science of print to ensure plate quality and performance is always at a maximum. When you partner with Trinity, you gain access to a full team of skilled designers eager to bring your print to plate.

How much of production is digital?

Digital printing has quickly infiltrated the flexo market as a strategic way to print short runs, prototypes, samples, and more. Digital machines print through inkjet technology and require no printing plates or anilox rolls. Therefore, executives are progressively replacing older flexo machines with digital technologies to diversify their product offerings and customer base. This shift to a hybrid print environment could dramatically decrease the number and frequency of printing plates needed in your day-to-day operations. What once was a profitable in-house investment may now be an obsolete plate-making machine taking up valuable real estate on your shop floor.

Printers operating with a flexo and digital fleet have less plates to produce and a new technology to master. Outsourcing your platemaking to Trinity can help you stay focused on what matters most! Optimize your shop floor for a profitable digital-flexo production mix and keeping customers happy with plate outsourcing.

Outsource Flexo Plate Making to Trinity Graphic

The only thing constant in life, is change. That is no different in the world of flexographic printing. Outsourced platemaking was once commonplace in the flexo market. As technology has grown, printers and converters have adapted to the new processes that support them. In today’s print environment, outsourced platemaking can increase uptime, reduce staffing needs, and save valuable real estate on your shop floor. No need to worry about your plate machine going down or finding the best designer for your clients. Since the 1960s, Trinity Graphic has served converters with top quality platemaking, design, and consulting services, diligently. As the industry continues to evolve, our team will always continue our legacy of platemaking so you can focus on your legacy in print. From narrow web to large format, Trinity has the equipment, designers, and experience to handle your plate making needs for years to come. Is it time to outsource your platemaking services? Contact our team to discuss your outsourcing options and get started today!

The only thing constant in life, is change. That is no different in the world of flexographic printing. Outsourced platemaking was once commonplace in the flexo market. As technology has grown, printers and converters have adapted to the new processes that support them. In today’s print environment, outsourced platemaking can increase uptime, reduce staffing needs, and save valuable real estate on your shop floor. No need to worry about your plate machine going down or finding the best designer for your clients. Since the 1960s, Trinity Graphic has served converters with top quality platemaking, design, and consulting services, diligently. As the industry continues to evolve, our team will always continue our legacy of platemaking so you can focus on your legacy in print. From narrow web to large format, Trinity has the equipment, designers, and experience to handle your plate making needs for years to come. Is it time to outsource your platemaking services? Contact our team to discuss your outsourcing options and get started today!