What Are Flexo Printing Plates?

Printing plates are a crucial component in the flexographic printing process. As a maker and innovator of flexo plates for over 40 years, Trinity Graphic knows what these precious canvases are and how to optimize them for ultimate performance. In this blog, we’ll stick to the basics and walk through what are flexo printing plates and their role in the flexo printing process.

What Are Flexo Printing Plates?

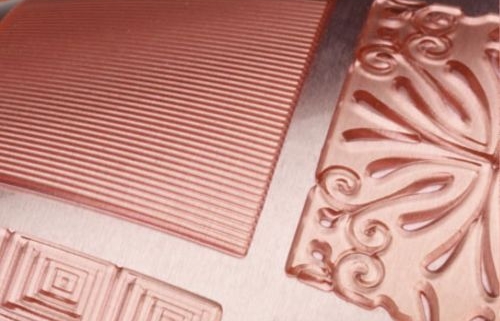

Flexo printing plates are flexible polymer sheets equipped with a raised image, like a stamp, to print on a wide range of materials, including paper, corrugated board, plastic, and even metallic films. How it works is: the plates are mounted onto the printing cylinder of the flexographic press and responsible for picking up a uniform layer of ink from the anilox. The raised surface of the plate will come into contact with the substrate as it passes through the press. As this happens, the ink on the plate’s raised areas will transfer onto the substrate, creating the printed image.

This print application is known for its ability to produce high-quality prints on various substrates, thanks to the flexible polymer plate and other important print innovations, making it suitable for a diverse range of applications.

Your choice of plate provider, material and design will have a direct impact on your print performance, for better or worse. It’s important to choose the right platemaker to ensure print quality and press performance. But first, you must understand the important features of flexo printing plates and their role in the flexo process:

Plate Composition

Material: Flexo printing plates are typically made from flexible photopolymer materials. Photopolymer plates are sensitive to ultraviolet (UV) light, allowing for precise image reproduction during the plate-making process.

Base: The photopolymer material of the plate is mounted on a flexible backing or base, often made of materials like polyester or metal.

Plate Making Process

Imaging: The flexo platemaking process begins with creating a digital image of the artwork to be printed. This image is then transferred onto the photosensitive surface of the flexo printing plate using various methods, such as laser engraving for digital plates or UV light exposure through a film negative for analog plates.

Development: After exposure, the unexposed areas are removed through a special development process, leaving a relief image that corresponds to the design to be printed.

Types of Flexo Plates

Analog Plates: Traditionally, flexo printing plates were made using analog processes, involving UV exposure through film negatives. These plates offer good print quality and are still widely used today.

Digital Plates: With advancements in technology, digital flexo plates have become increasingly popular. These plates are imaged directly using computer-to-plate (CTP) systems, offering more precision over plate details and quicker turnaround times.

Trinity Graphic: Your Flexo Printing Plates Partner

Flexo printing plates play a pivotal role in the flexographic printing process, and the choice of plate material, design and supplier will make all the difference. Trinity Graphic is honored to be a preferred supplier of flexo plates for over 40 years. Advances in plate-making technology continue to enhance the quality and efficiency of our flexo printing and when quality matters, printers choose Trinity. Contact our team to discuss our platemaking products and solutions and see the difference Trinity can make in your flexo print operations.